FULL-SERVICE TESTING UNDER EXTREM ENVIRONMENTAL CONDITIONS

In the automotive industry, it is crucial that vehicles and their components can withstand extreme environmental conditions. Climatic influences such as temperature and humidity affect almost every product, component and material. They have a significant influence on its performance and service life. To test the reliability of your product under the expected conditions, we offer a variety of test methods in our ISO 17025, TISAX® accredited laboratory. We perform tests according to industry standards & norms for all international and national automotive manufacturers (OEMs). Thanks to our expertise in ageing testing and environmental simulation, we can ensure that your products meet the highest quality and safety standards.

OUR TESTING PORTFOLIO

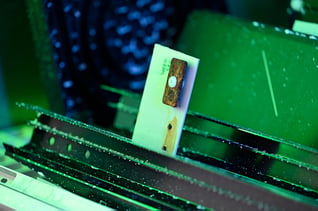

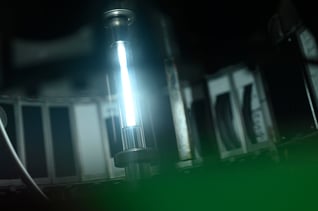

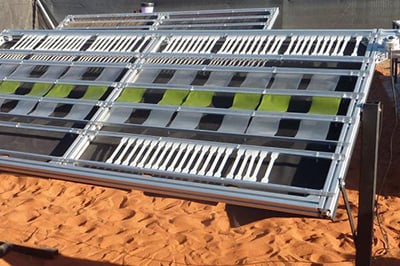

UV resistance

TEST FACILITIES

Test chambers

0,9 m³ - 46 m³

Range of temperature

-60°C to +180°C

rel. humidity

10 % - 100 %

TEST STANDARDS, OEM SPECIFICATIONS, METHODS & MORE

- BMW PR 306.5 , PR 303.5, GS 95024-3-1

- Mercedes-Benz DBL 5471

- VW PV 1200

- VW 80000

- DIN 75220

- VDA 230-219

- Ford FLTM BO 040-01

- Jaguar Landrover TPJLR.52.353

- LV 124

- Nissan NES M0132

- PSA D47 1309

- Rivian RTS.1741

- VinFast VFDST00053600

- and more

TYPICAL TEST METHODS BEFORE AND AFTER AGEING

Tests performed before and after aging include various mechanical, physical and chemical tests to evaluate the effects of aging processes on materials and components. Here are some of the most common tests

BEFORE

- Visual evaluation

- Color and gloss measurement

- Photogrammetry

- Hot light fastness/ hot light ageing

- Scratch test

- Abrasion resistance

- Burning behavior

- Emission and odor testing in vehicle interiors

AFTER

- Visual evaluation

- Color and gloss measurement

- Photogrammetry

- Peel test

- Foam adhesion

- Hardness test

- etc.

- Business Development Team

- Other requests

_550px.jpg?width=300&name=Probenhalter_Rendering_151112_1_bueckech-(1)_550px.jpg)