Fogging

Determination of the fogging behavior of materials used in vehicle interiors

FOGGING TEST IN THE

AUTOMOBILE INTERIOR

VOC TESTS ON MATERIALS, SPARE PARTS AND COMPONENTS

To protect the occupants of vehicles, the materials, individual components and even complete assemblies used in the interior are tested for their potential to release so-called "VOCs". VOCs" are volatileorganic compounds that can escape from materials into the surrounding atmosphere. Such material emissions occur with most non-metallic materials and can affect the well-being of vehicle occupants and cause potential health risks .

The VOC test methods required by vehicle manufacturers aim to identify the substances released under the test conditions and to determine their quantities. Depending on whether material samples, composite materials, individual parts or complete assemblies and components are to be tested, completely different laboratory methods are used .

The emission behavior of material samples is often determined using so-called "direct methods" (e.g. VDA 277 and VDA 278), in which the occurrence of emissions and their detection by a measuring system are carried out directly in one go. On the other hand, there are test methods in which the generation of VOC emissions and their analysis are decoupled in terms of time and space. In such indirect methods (e.g. ISO 12219-1, ISO 12219-2, ISO 12219-3, ISO 12219-4, ...), collection media are used to capture the VOC emissions and analyze them at a later time.

In particular, the performance of emission tests requires compliance with specific requirements for the test environment, the equipment used and the qualified laboratory staff. VOC tests are therefore generally carried out by independent accredited testing laboratories.

Are you looking for an exam? Standard? Specifications?

Accredited & certified tests

CONTACT OUR EXPERTS

Description. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et

- Tab Title

- 01 Purpose of VOC test methods

- 02 Test methods

- 03 Test procedure

Purpose of VOC test methods

- Identification of volatile organic chemical substances (VOC emissions ) released from materials, individual parts, components or assemblies

- Quantitative determination of the emissions released as a total value and, as a rule, also of the individual substance emissions

- Identification of potential hazards through substance classifications according to relevant substance lists, such as EU-CLP, REACH, etc .

Test methods

- static headspace analysis (VDA 277, VW PV 3341... )

- direct thermal desorption (VDA 278, ISO/FDIS 12219-11... )

- Bag testing (ISO 12219-2, ISO 12219-9... )

- Microchamber testing (ISO 12219-3, TPJLR 52.104... )

- Component chamber testing (ISO 12219-4, BMW GS 97014-3... )

- Complete vehicle testing (ISO 12219-1... )

Test procedure

- Weighing or loading of the measuring system with defined samples

- Thermal loading of the samples under standardized laboratory conditions

- Collection of occurring emissions, if necessary on desorption tubes with collection media (indirect test methods )

- Chromatographic separation of the substance mixtures and subsequent detection in the measuring system

- Evaluation and interpretation of the measurement

- Comparison/comparison of the measurement results with the applicable target and limit values

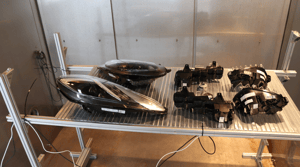

TYPICAL MATERIALS THAT ARE TESTED

The fogging test in automotive testing examines various materials that are used in vehicle interiors. The most important materials that are subjected to this test are

Various types of plastics, for dashboards, consoles and other interior components

Especially for seat covers and steering wheel covers

Fabrics used for seat covers, headliners and other interior trims

As an alternative to genuine leather for various interior components

Rubber-like materials that are used in various vehicle parts

Used to connect various components in the vehicle interior

Various surface inspections for interior parts

Especially for upholstery and insulation

Combinations of different materials used in the vehicle interior

Newer, environmentally friendly alternatives to conventional plastics

Frequently asked questions about the fogging test

The sample quantities required for a fogging test depend on the standard and the test method used. Here are the general guidelines:

1. standard DIN 75201 (type A and type B)

-

Type A (glass plate method):

A sample quantity of 10 cm² is typically required. The sample is placed on a heated plate in a sealed chamber and the volatiles released condense on a glass plate above. -

Type B (aluminum foil method):

Similar to type A, a sample volume of approximately 10 cm² is used. However, the volatile substances condense on a cooled aluminum foil.

2. standard ISO 6452 (international standard)

- Sample quantity:

Again, a sample size of about 10 cm² is typically required to evaluate the amount of volatiles released at elevated temperature.

3. other specific requirements

Depending on the specific requirements of the customer or OEM standards, sample quantities may vary. It is important to check the respective standards or test requirements carefully.

Method A - Reflectometric method:

- Principle: This method measures the change in reflectivity on a glass plate on which volatile components from the material sample are deposited.

- Procedure: A material sample is heated in a beaker while a glass plate above it is cooled to 21°C. The temperature difference causes the volatile components to condense on the glass plate. The reflectance index of the fogged glass plate is then measured to determine the amount of condensed material.

- Application: This method is particularly suitable for materials for which an exact determination of the optical fog effect is required.

Method B - Gravimetric method:

- Principle: This method measures the weight of condensed volatiles on an aluminum foil.

- Procedure: The material sample is heated in a beaker while an aluminum foil disc is cooled to 21°C. After 16 hours, the amount of condensed material on the foil is weighed.

- Application: This method is ideal for an accurate quantitative determination of the amount of condensed volatiles.

CONTACT US

EMISSIONS & ODOR

Formaldehyd in Fahrzeugen: Herausforderungen für die Automobilindustrie

Read moreStellantis: Freigabe für Emissionsprüfungen erfolgreich (VIAQ)

Read moreVDA 277 vs. VDA 278: Was ist der Unterschied?

Read moreGeruchsunterschiede bei Polypropylen: Die Rolle von Faserverstärkung und Verarbeitungsparametern

Read moreWarum sind die Einheiten der Ergebnisse von Prüfungen der Werkstoffemissionen eigentlich so unterschiedlich?

Read moreGrenzwerte für Formaldehyd und Formaldehydabspaltern in Fahrzeugen

Read moreFREQUENTLY ASKED QUESTIONS ABOUT VOC EXAMS

Common test standards include VDA 278, ISO 16000-6 and ASTM D5116. Typical methods include gas chromatography-mass spectrometry (GC-MS) to identify specific VOCs and sum measurements to quantify the total VOC load. The choice of method depends on the customer's requirements or legal requirements.