QUALITY REQUIREMENTS FOR ELECTRICAL COMPONENTS

E-components under voltage

Today's vehicles are true masterpieces of engineering, packed with sophisticated electronic components and systems, comparable to a computer on wheels! It is vital that your electronic vehicle components can withstand the most extreme environmental conditions and quality requirements to ensure that they meet the demanding international standards of the automotive industry.

LV 124 standard - The gold standard in the automotive industry

In 2013 the standard LV 124 was developed by representatives of German car manufacturers such as Audi, BMW, Mercedes-Benz, Volkswagen and Porsche. This standard specifies various test scenarios, their requirements and conditions for simulating electrical faults in the electrical system of a vehicle up to 3.5 tons while driving. The tests described in LV 124 are included in their own OEM specifications (e.g. VW 80000, MBN LV124, BMW GS 95024-3-1 etc.). The aim is to minimize the risk of failure and to eliminate electrical faults that occur at short notice.

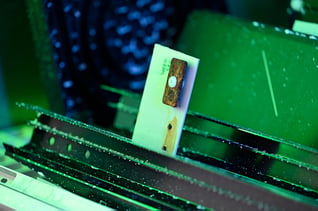

Test procedure

The components are subjected to various climatic, electrical or mechanical loads. They are energized with different operating modes before, during and after the test. Electrical values such as current, voltage and resistance are recorded. In the best case, the control unit is supplied together with the samples. This ensures that the samples are controlled correctly and the correct key figures are recorded. The control system and the recording of the values are of course agreed with you in advance.

ELIMINATE WEAKNESSES - BEFORE IT'S TOO LATE!

Our common goal: Your components should meet the highest quality standards and perform reliably. Let's eliminate weak points together before they cause problems!

SPECIFICATIONS

Your requirements - Our expertise

- BMW GS 95024‑3‑1

- BMW GS 95024-2

- Mercedes-Benz MBN LV 124

- Volkswagen VW 80000

- Tesla TS-0002476

- Ford CETP: 00.00-E-412

- Stellantis (FCA) CS.00056

- General Motors GMW3172

- MAN M 3256-1

- Scania TB1900

TEST DETAILS

- M-01 Free fall

- M-02 Stone impact test

- M-03 Dust test

- M-04 Vibration test

- M-05 Mechanical shock

- M-06 Mechanical shock durability testing

- M-07 Coolant circuit pressure pulsation test

- M-08 Protection against foreign bodies - IP0x to IP4x, A, B, C, D

- M-09 Leak test

- K-01 High/low-temperature aging

- K-02 Incremental temperature test

- K-03 Low-temperature operation

- K-04 Repainting temperature

- K-05 Thermal shock (component)

- K-06 Salt spray test with operation, vehicle exterior

- K-07 Salt spray test with operation, vehicle interior

- K-08 Damp heat, cyclic

- K-09 Damp heat, cyclic (with frost)

- K-10 Water protection – IPX0 to IPX6K

- K-11 High-pressure cleaning/steam-jet cleaning

- K-12 Thermal shock with splash water

- K-13 Thermal shock – immersion

- K-14 Damp heat, steady state

- K-15 Condensation test with assemblies

- K-16 Thermal shock (without housing)

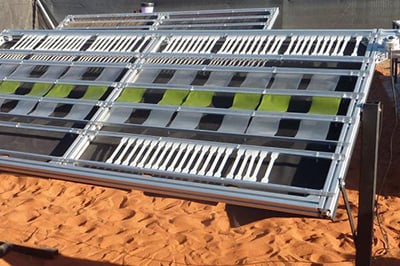

- K-17 Solar radiation

- K-18 Harmful gas test

- K-19 Climate test for components with watertight housings

- C-01 Chemical tests

- L-01 Service life test - mechanical/hydraulic durability testing

- L-02 Service life test - high-temperature durability testing

- L-03 Service life test - temperature cycle durability testing

ACCREDITATIONS, CERTIFICATES &

OEM RELEASES

DIN EN ISO/ IEC 17025, ISO 9001, VDA 6.2, TISAX®,

various OEM approvals and many more.

WHY IMAT?

GLOBAL STANDARD

You can expect a high level of quality worldwide.

We work according to DIN EN ISO 17025, ISO 9001, TISAX® and VDA 6.2. or international OEM requirements.

FULL SERVICE PROVIDER

We are able to test most off all requirements of a material or component. For you, this means uncomplicated, convenient processing of orders.

REQUEST FOR QUOTATION

CONTACT US

- Business Development Team

- Other requests