Fogging

Determination of the fogging behavior of materials used in vehicle interiors

FOGGING TEST IN THE

AUTOMOBILE INTERIOR

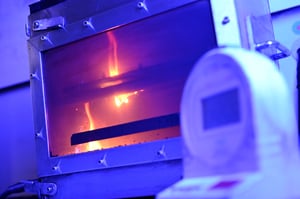

DETERMINATION OF THE BURNING BEHAVIOR

Determining the burning behavior of materials in vehicle interiors is a central component of safety requirements in the automotive industry. All materials that are used in or limit the passenger compartment must comply with legal requirements and OEM standards. The burning rate is measured under standardized conditions to ensure that materials meet the requirements.

In addition to testing finished components and materials, imat also offers the option of having sample plates made from granulate and testing them if the sample sizes for small parts are not sufficient. With these comprehensive services, imat supports automotive manufacturers and suppliers in validating their materials according to the required standards.

- Typical materials and components that are tested

- Typical test procedure

Typical materials and components that are tested

- Plastics: door panels, instrument panels, console panels, cable sheathing, etc.

- Textiles and foams: seat covers, headliners, acoustic foams, upholstery, etc.

- Leather and artificial leather for seats and trim.

- Examples of other components/composite materials: sun visors, headliners, parcel shelves, floor mats, cable ducts, etc.

Typical test procedure

- Selection of test methods: In consultation with you, we select the appropriate test methods based on the specific requirements.

- Sample preparation: The samples are prepared in accordance with the standards.

- Typical sample sizes are, for example, in accordance with FMVSS 302/DIN 75200: 356 mm x 100 mm x material thickness ≤ 13 mm

- Performance of the test: The samples are exposed to standard-compliant conditions to document their burning behavior and burning rate.

- Test report: After completion of the tests, you will receive a report with valid test results.

Firing

test methods

- FMVSS 302 / US 571.302 (TP 302-03) 49 CFR 571 302 (USA) (Federal Motor Vehicle Safety Standard)

- DIN 75200

- VSTD 19-1 (191) - § 19-1.5 horizontal test (Taiwan)

- DBL 5307 (Mercedes-Benz previously Daimler)

- TL 1010 (Volkswagen)

- GS 97038 (BMW)

- PTL 8501 / VW 96243 (Porsche)

- GB 8410 (China)

- D45 1333 (PSA / Stellantis)

- VCS 5031,19 (Volvo)

- GMW 3232 (GM, General Motors)

- ISO 3795

- and much more.

Fogging test methods

- DIN 75201-A (reflectrometric)

- DIN 75201-B (gravimetric)

- PV 3015 (Volkswagen)

- GMW 3235-A (General Motors Worldwide)

- PSA D45 1727

- and much more.

Are you looking for an exam? Standard? Specifications?

Accredited & certified tests

CONTACT OUR EXPERTS

Description. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et

- Tab Title

Frequently asked questions about the fogging test

The sample quantities required for a fogging test depend on the standard and the test method used. Here are the general guidelines:

1. standard DIN 75201 (type A and type B)

-

Type A (glass plate method):

A sample quantity of 10 cm² is typically required. The sample is placed on a heated plate in a sealed chamber and the volatiles released condense on a glass plate above. -

Type B (aluminum foil method):

Similar to type A, a sample volume of approximately 10 cm² is used. However, the volatile substances condense on a cooled aluminum foil.

2. standard ISO 6452 (international standard)

- Sample quantity:

Again, a sample size of about 10 cm² is typically required to evaluate the amount of volatiles released at elevated temperature.

3. other specific requirements

Depending on the specific requirements of the customer or OEM standards, sample quantities may vary. It is important to check the respective standards or test requirements carefully.

Method A - Reflectometric method:

- Principle: This method measures the change in reflectivity on a glass plate on which volatile components from the material sample are deposited.

- Procedure: A material sample is heated in a beaker while a glass plate above it is cooled to 21°C. The temperature difference causes the volatile components to condense on the glass plate. The reflectance index of the fogged glass plate is then measured to determine the amount of condensed material.

- Application: This method is particularly suitable for materials for which an exact determination of the optical fog effect is required.

Method B - Gravimetric method:

- Principle: This method measures the weight of condensed volatiles on an aluminum foil.

- Procedure: The material sample is heated in a beaker while an aluminum foil disc is cooled to 21°C. After 16 hours, the amount of condensed material on the foil is weighed.

- Application: This method is ideal for an accurate quantitative determination of the amount of condensed volatiles.

CONTACT US

MATERIAL TESTS

Medienbeständigkeit in der Automobilbranche

Read moreWebinar Insights: Grundlagen der Dickenmessung bei Textilien

Read moreOptimierung der Automobilsitze: Nahtqualität im Fokus

Read moreMace Snag Prüfung: Qualitätssicherung bei Automobiltextilien

Read moreWie Automobilzulieferer die richtigen Prüfnormen finden

Read moreWas versteht man unter Umweltsimulation im automobilen Kontext?

Read moreFREQUENTLY ASKED QUESTIONS ABOUT THE FOGGING TEST

⇒ Request a quote now

Yes, in addition to flammability, materials can also be tested for the toxicity of the resulting fumes. This is often done in a smoke density chamber using FTIR spectroscopy (Fourier transform infrared spectroscopy). This method is used to analyze the chemical composition of the smoke gases in order to identify potentially hazardous substances. This helps to evaluate materials not only in terms of their flammability, but also with regard to the safety of the occupants.

Disclaimer

The information provided is based on many years of experience and is for general information purposes only. No guarantee is given for the correctness, completeness or topicality of the contents. Warranty claims cannot be derived from this information and the rights of third parties remain unaffected. Details on sampling, sample preparation, test equipment, test methods and the performance and evaluation of test results can be found in the latest versions of the underlying standards.