Your first choice partner for professional weathering tests within the automotive industry.

We are specialized in comprehensive weathering, UV resistance, and other essential testing services.

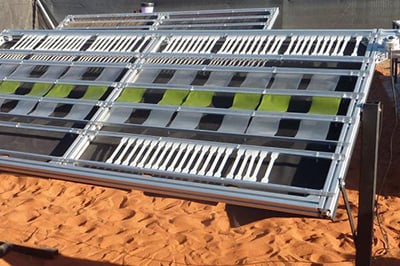

In the automotive sector, weathering testing stands as a crucial method for assessing the long-term resilience of materials like plastics, textiles, and composite materials against environmental factors. These tests encompass both natural, outdoor weathering, and controlled laboratory settings for artificial weathering. Key weathering influencers include UV radiation, temperature fluctuations, and humidity.

Our weathering and UV resistance test methodologies offer precise simulations of diverse environmental conditions, including UV radiation, humidity, precipitation, and temperature, all conducted under standardized laboratory settings. These approaches streamline the evaluation of material durability, ensuring swift and accurate assessments while maintaining consistency in test results.

With a team of highly skilled specialists and cutting-edge testing equipment, we execute accredited and certified weathering tests promptly and efficiently, adhering strictly to relevant norms and standards. Trust us to deliver top-notch service and reliable results for all your weathering testing needs.

imat - First choice in automotive validation & consulting.

Typical test methods

Typical test procedures

Relevant standards for test methods:

- DIN EN ISO 105-B02

- DIN EN ISO 105-B06

- DIN EN ISO 4892-2

- DIN EN 513

- ISO 16474-2

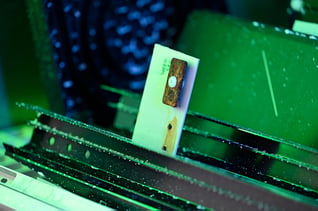

imat is equipped with a range of rapid weathering devices that use UV fluorescent lamps as a light source. These devices focus on exposing the samples exclusively to the high-energy UV spectrum of natural solar radiation. Therefore, these tests are primarily used for materials whose spectral sensitivity is primarily in the wavelength range of 300 to 400 nm.

- ASTM D7869

- BMW AA-0235 / DIN EN ISO 16474-2 (DIN EN ISO 4892-2)

- BMW AA-0235 / SAE J2527

- BMW AA-0236 / DIN EN ISO 4892-2 (Procedure A - BST 65 °C)

- DBL 5578, Tab. 2, 4.12.4 / LV 28 (Florida-Modus)

- DBL 5578, Tab. 2, 4.12.4 / LV 28 (Kalahari-Modus)

- DIN EN ISO 105-B06 (Exp. no. 3) according to, BST 90°C

- DIN EN ISO 105-B06 (Exposure condition no. 5)

- DIN EN ISO 4892-2 (Method A - BST 65°C)

- DIN EN ISO 4892-2 (method A)

- DIN EN ISO 4892-2 (Method B - BST 100°C)

- Fiat 50451/01 - Method A (carbon arc)

- Fiat 50451/01 - Method B (xenon arc)

- Fiat 50471/01

- Fiat Chrysler FCA 50451/01/ LP.7M005 - Method B (xenon arc)

- Fiat Chrysler FCA 50451/01/ LP.7M005 - Methode A (Kohlebogen)

- Ford FLTM BO 116-01

- GMW 14162-B

- GMW 14162-C / DIN EN ISO 105-B06, expsoure condition no. 1

- GMW 14162-D

- Honda HES D 6601-99A / JIS B 7754

- Hyundai/KIA MS 210-05 § 4.5

- Hyundai/KIA MS 300-32 § 4.14.1

- MBN 10494-6 § 5.9.1

- MBN 51000-5 § 5.3 HLA (DIN EN ISO 105-B06, Exposure condition no. 3)

- MBN 55555-5 § 5.4 (Florida mode)

- MBN 55555-5 § 5.4 (Kalahari mode)

- Nissan NES M0135, Method 1-II-2 (WOM / Xenon / Interiorn)

- Porsche PPV 4014-A / VW 96378 (SST 90 °C)

- Porsche PPV 4014-B / VW 96378 (SST 65 °C)

- PSA D27 1389

- PSA D47 1431

- Renault D47 1431

- SAE J1885

- SAE J2527

- Suzuki SES N 3293/3292 (WAL-1)

- Suzuki SES N 3293/3292 (WAL-2)

- Toyota TSL 0601 G (Xenon arc)

- Toyota TSL 0601 G § 5.5 (Xenon arc)

- Toyota TSM 0501 G § 9.20 (WOM / Xenon)

- VDA 621-430-1997 (CAM 180)

- VDA 75202 (based on, BST 90 °C)

- Volvo STD 423-0061

- Volvo VCS 1026,82429

- Volvo VCS 1027,3379 / DIN EN ISO 4892-2 (Procedure A - BST 65 °C)

- Volvo VCS 1027,359 (DIN EN ISO 4892-2)

- VW PV 1502

- VW TL 52065 § 5.8 / VW PV 3930 (24 h)

Relevant standards:

- VW PV 3929

- Mercedes-Benz MBN 10506

- Mercedes-Benz MBN 51000-5 § 5.4

- Mercedes-Benz MBN 55555-5 § 5.4

- DBL 5578

- BMW PR 231

- BMW GS 93052-3 § 4.3.1

Relevant standards:

- VW PV 3930

- Mercedes-Benz MBN 10505

- Mercedes-Benz MBN 55555-5 § 5.4

- DBL 5578

- BMW PR 231

- BMW GS 93052-3 § 4.3.2

Relevant standard:

- VW PV 1303

Follow-up tests after weathering exposure

- Evaluation of changes in brightness, gloss and color

- Bending tests

- Testing the adhesive strength

- Gloss measurements

- Testing the peel strength

- Stone impact test

- Burning tests

- Impact and notched bar impact tests

- Tensile tests

- Color measurements

- Microscopy

- Steam jet testing

Why imat?

GLOBAL STANDARD

You can expect a high level of quality worldwide.

We work according to DIN EN ISO 17025, ISO 9001 and VDA 6.2. or international OEM requirements.

FULL SERVICE

We are able to test most off all requirements of a material or component. For you, this means uncomplicated, convenient processing of orders.

EXPERTISE

Highly qualified and motivated employees support you in your daily challenges. Benefit from over 30 years of experience in the automotive world.

REQUEST A NON-BINDING QUOTE NOW

Accreditations/ Certificates

TRUSTED BY AUTOMOTIVE LEADERS

Worldwide, automotive manufacturers such as Mercedes-Benz, BMW, Porsche, Tesla & Co. as well as suppliers trust in our expertise and reliability.

_550px.jpg?width=300&name=Probenhalter_Rendering_151112_1_bueckech-(1)_550px.jpg)