Fogging

Determination of the fogging behavior of materials used in vehicle interiors

FOGGING TEST IN THE

AUTOMOBILE INTERIOR

MICROCHAMBER TESTS FOR AUTOMOTIVE INTERIOR MATERIALS AND COMPOSITES

Micro test chambers are an innovative solution for the precise emission measurement of volatile organic compounds (VOCs), aldehydes and other pollutants released by automotive materials. These test chambers are specifically designed to analyze smaller material samples of plastics, textiles, leather, foams and films under controlled conditions without sacrificing accuracy or reliability.

The ability to test small samples significantly reduces the amount of testing required while still providing meaningful results. The moderately selected test temperatures compared to other material tests are based on the component chamber tests .

Micro test chambers can play a key role, particularly in the development of new materials and in the selection of low-emission alternatives. Using this method, manufacturers can identify high-emission materials early on in the development process and specifically test lower-emission options. This not only contributes to improving the air quality in the vehicle interior, but also helps to assess compliance with regulatory requirements such as the formaldehyde restriction under REACh. At the same time, it enables the cost-efficient development and testing of new materials without wasting large amounts of resources.

Thanks to their compact size and high precision, micro test chambers are also ideal for continuous quality control of materials. Manufacturers can ensure that each batch of material meets the necessary emission requirements before it goes into production. This allows you to identify and rectify problems at an early stage before they lead to major challenges in series production.

Are you looking for an exam? Standard? Specifications?

Accredited & certified tests

CONTACT OUR EXPERTS

Description. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et

- Tab Title

- 01 Purpose of the microchamber test

- 02 Test procedure

Purpose of the microchamber test

- Determination of characteristic data for materials and composite materials with regard to their VOC emissions and, if applicable, selected individual substances such as formaldehyde or similar.

- Determination of emission rates of the volatile substances released

- Identifying critical substances in the emissions of vehicle interior materials

Test procedure

Bulk Mode

- Preparation of one or more geometric test specimens for the test

- Preconditioning the microchamber to the test conditions (temperature, carrier gas flow, etc. )

- Loading the cylindrical chamber with the test specimen

- Equilibrating the sample to the test conditions over a defined period of time

- Guide the outgoing exhaust air flow for sampling via suitable collection media

- Thermally desorb the VOCs from the screening collection media or elute specific target substances from corresponding adsorbents using solvents.

- Chromatographic separation of the VOC substance mixture with subsequent detection in the measuring system

- Evaluating and interpreting the measurement results

- Comparison of the measurement results with the applicable target and limit values

Surface Mode

- Preparing a flat test specimen with the diameter of the microchamber for testing

- Equipping the microchamber with a clamping device for surface tests

- Preconditioning the microchamber to the test conditions (temperature, carrier gas flow, etc. )

- Loading the microchamber with the test specimen directly under the chamber lid to test only the surface emissions

- Equilibrate the sample to the test conditions over a defined period of time

- Guide the outgoing exhaust air flow for sampling via suitable collection media

- Thermally desorb the VOCs from the screening collection media or elute specific target substances from appropriate adsorbents using solvents.

- Chromatographic separation of the VOC substance mixture with subsequent detection in the measuring system

- Evaluating and interpreting the measurement results

- Comparison of the measurement results with the applicable target and limit values

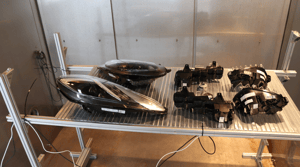

TYPICAL MATERIALS THAT ARE TESTED

Microchamber testing in automotive testing examines various materials that are used in vehicle interiors. The most important materials that are subjected to this test are

Various types of plastics, for dashboards, consoles and other interior components

Especially for seat covers and steering wheel covers

Fabrics used for seat covers, headliners and other interior trims

As an alternative to genuine leather for various interior components

Rubber-like materials that are used in various vehicle parts

Used to connect various components in the vehicle interior

Various surface inspections for interior parts

Especially for upholstery and insulation

Combinations of different materials used in the vehicle interior

Newer, environmentally friendly alternatives to conventional plastics

Frequently asked questions about the fogging test

The sample quantities required for a fogging test depend on the standard and the test method used. Here are the general guidelines:

1. standard DIN 75201 (type A and type B)

-

Type A (glass plate method):

A sample quantity of 10 cm² is typically required. The sample is placed on a heated plate in a sealed chamber and the volatiles released condense on a glass plate above. -

Type B (aluminum foil method):

Similar to type A, a sample volume of approximately 10 cm² is used. However, the volatile substances condense on a cooled aluminum foil.

2. standard ISO 6452 (international standard)

- Sample quantity:

Again, a sample size of about 10 cm² is typically required to evaluate the amount of volatiles released at elevated temperature.

3. other specific requirements

Depending on the specific requirements of the customer or OEM standards, sample quantities may vary. It is important to check the respective standards or test requirements carefully.

Method A - Reflectometric method:

- Principle: This method measures the change in reflectivity on a glass plate on which volatile components from the material sample are deposited.

- Procedure: A material sample is heated in a beaker while a glass plate above it is cooled to 21°C. The temperature difference causes the volatile components to condense on the glass plate. The reflectance index of the fogged glass plate is then measured to determine the amount of condensed material.

- Application: This method is particularly suitable for materials for which an exact determination of the optical fog effect is required.

Method B - Gravimetric method:

- Principle: This method measures the weight of condensed volatiles on an aluminum foil.

- Procedure: The material sample is heated in a beaker while an aluminum foil disc is cooled to 21°C. After 16 hours, the amount of condensed material on the foil is weighed.

- Application: This method is ideal for an accurate quantitative determination of the amount of condensed volatiles.

CONTACT US

Formaldehyd in Fahrzeugen: Herausforderungen für die Automobilindustrie

Read moreStellantis: Freigabe für Emissionsprüfungen erfolgreich (VIAQ)

Read moreVDA 277 vs. VDA 278: Was ist der Unterschied?

Read moreGeruchsunterschiede bei Polypropylen: Die Rolle von Faserverstärkung und Verarbeitungsparametern

Read moreWarum sind die Einheiten der Ergebnisse von Prüfungen der Werkstoffemissionen eigentlich so unterschiedlich?

Read moreGrenzwerte für Formaldehyd und Formaldehydabspaltern in Fahrzeugen

Read moreFREQUENTLY ASKED QUESTIONS ABOUT MICROCHAMBER TESTING

Micro test chambers are suitable for a wide range of materials such as plastics, textiles, leather, foams and composites used in vehicle interiors.